Fibers improvement

OUR BRAND – FLEXTEC

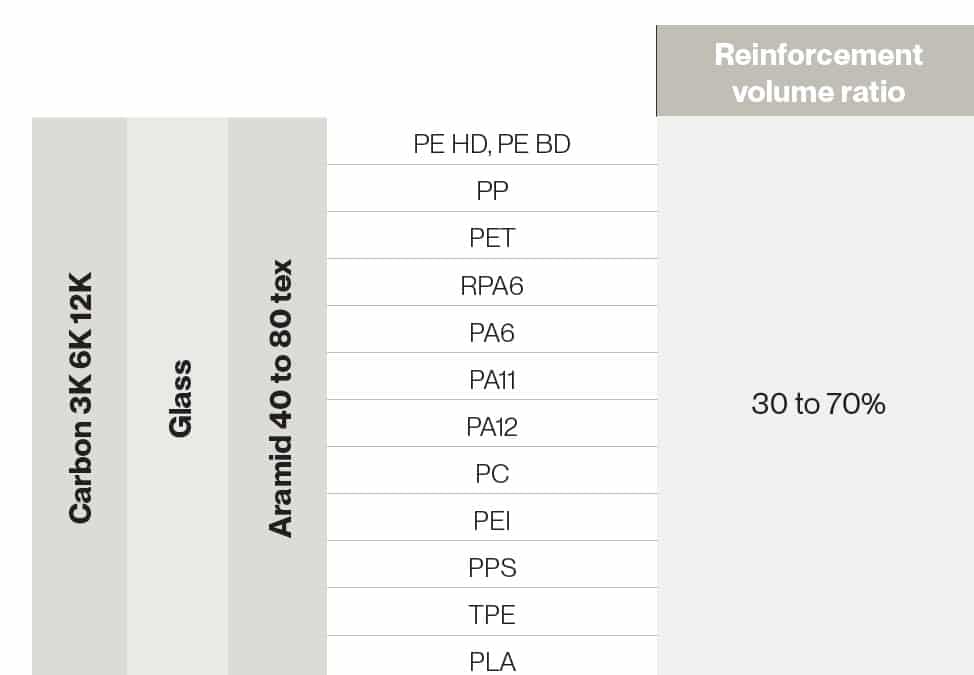

Our teams are experts in numerous yarn processing technologies, offering functionalization options through liquid impregnation, powder coating, or extrusion coating. The variety of our coating technologies allows us to meet the most demanding requirements.

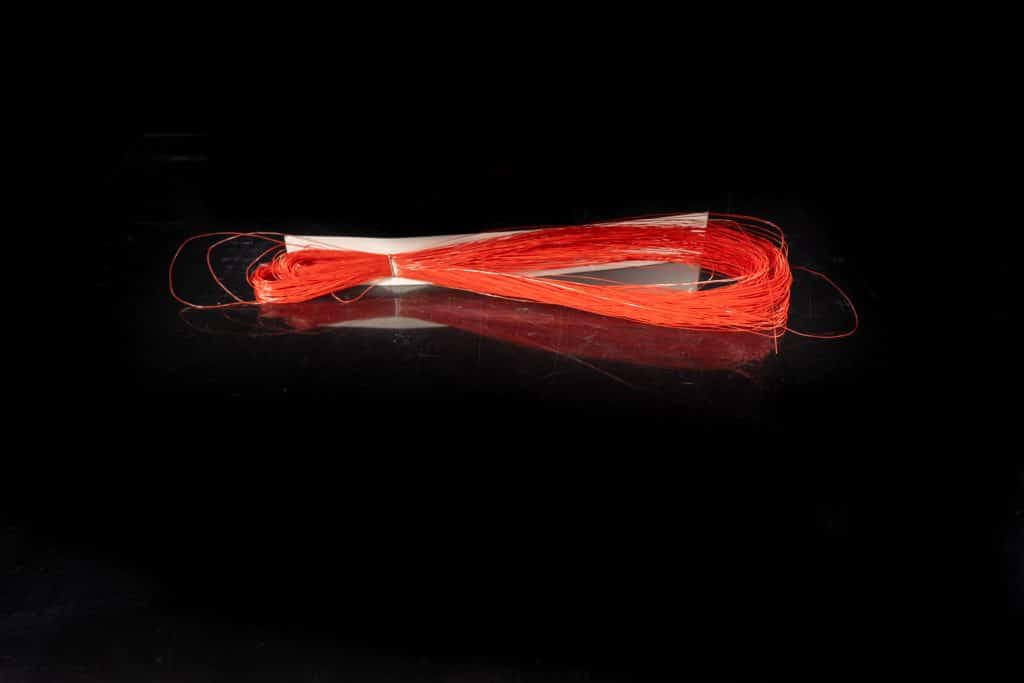

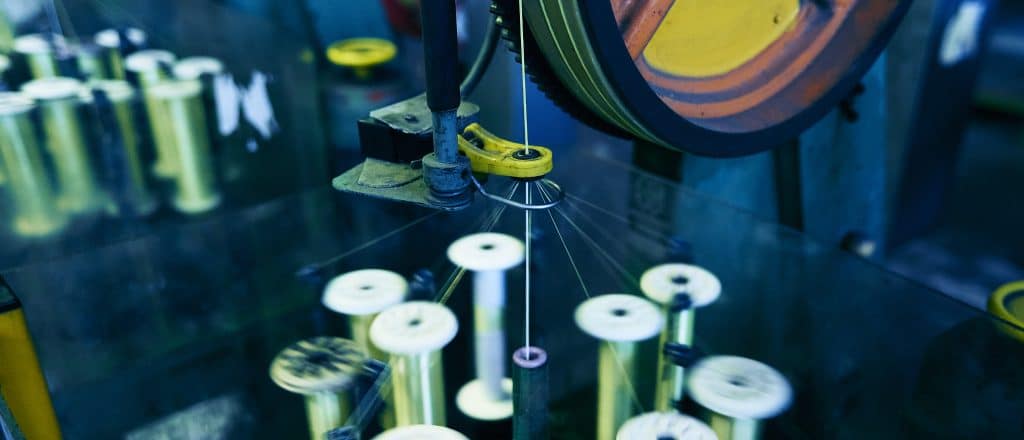

Different yarns can be assembled according to the end use: Polyester / Fiberglass / Carbon / Basalt / Aramid / Flax / Hemp.

Finally, the final product can be braided, overbraided, or even comelized.

• Areas of application: sports and leisure, aeronautics, railways, technical textiles, construction, etc.

FIBER ASSEMBLY AND COMMINGLING

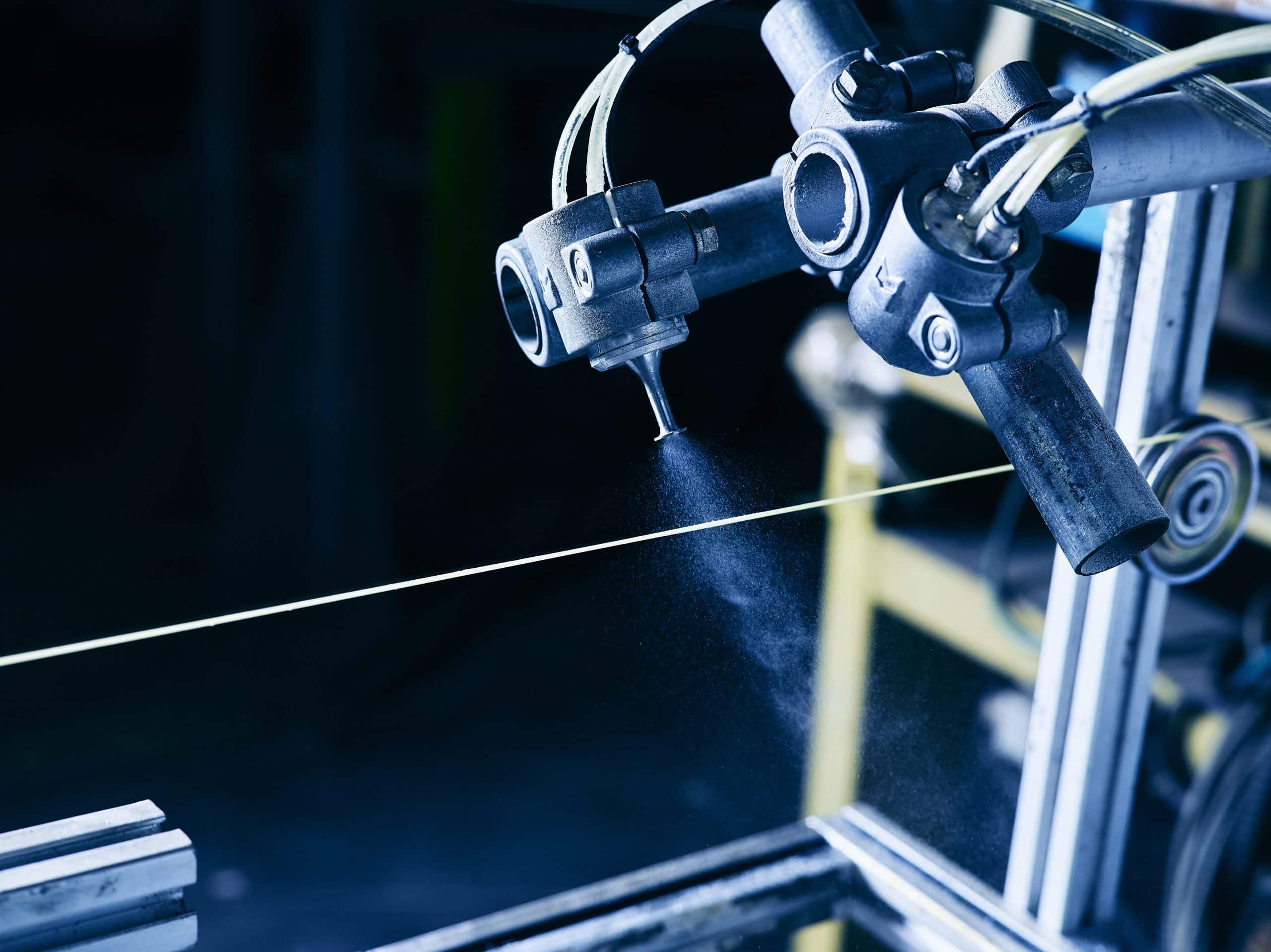

FIBER COATING

Functionalization by liquid impregnation, powder coating, or extrusion coating.

Applications: fire retardant, antibacterial, water repellent, abrasion resistant, etc.

ARAMID OVERBRAIDING

Overbraiding, or overlay braiding, consists of applying a finishing braid. This additional layer gives the final product enhanced mechanical properties: cohesion, flexibility, anti-rotation, and better load distribution.

CEFOR

Using this process, we impregnate pre-braided aramid fibers with polyurethane resin.

A technology unique to the COUSIN® group.

RUBACEF

Through this process, we apply a polyurethane coating to aramid fibers.

This may be necessary when increased abrasion resistance is required.

We also perform