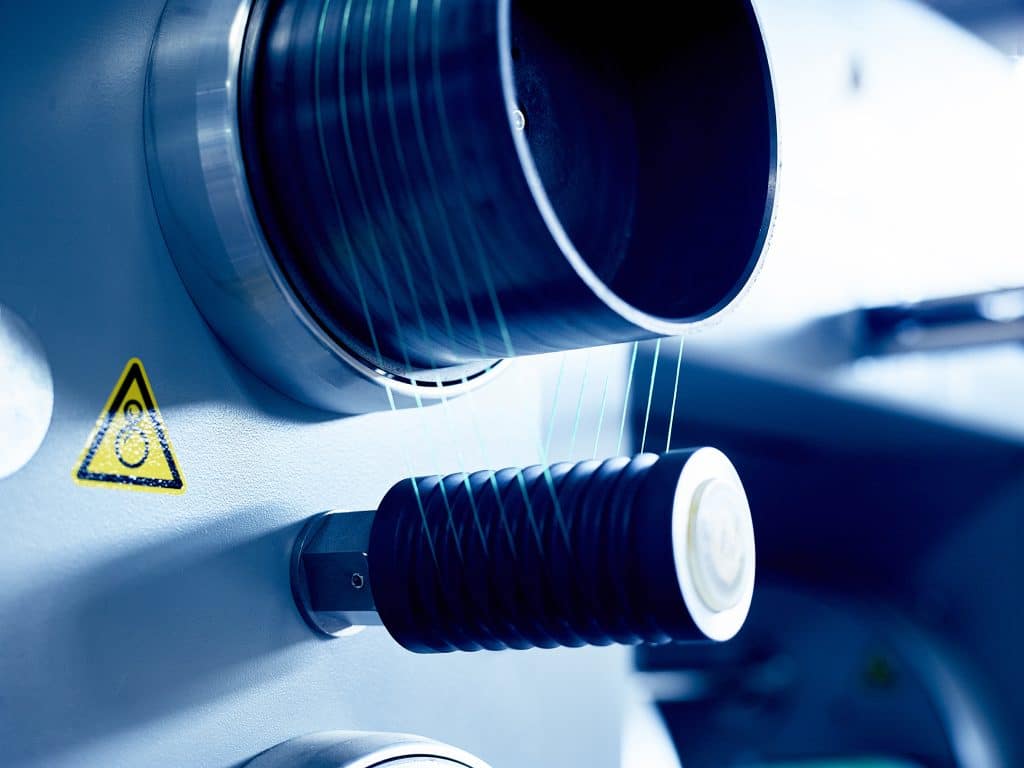

Fibers and Composites

A project?

Cousin® develops your industrial project

A high-performance industrial textile cable project?

Our design office develops your product with you.

Our process

Submit your request using our contact form:

- Requirement

- End use

- Environment in which your product will be used

- Desired technical characteristics

- Desired length and diameter

- COUSIN® brand or white label

Our design office will then examine the feasibility of your request.

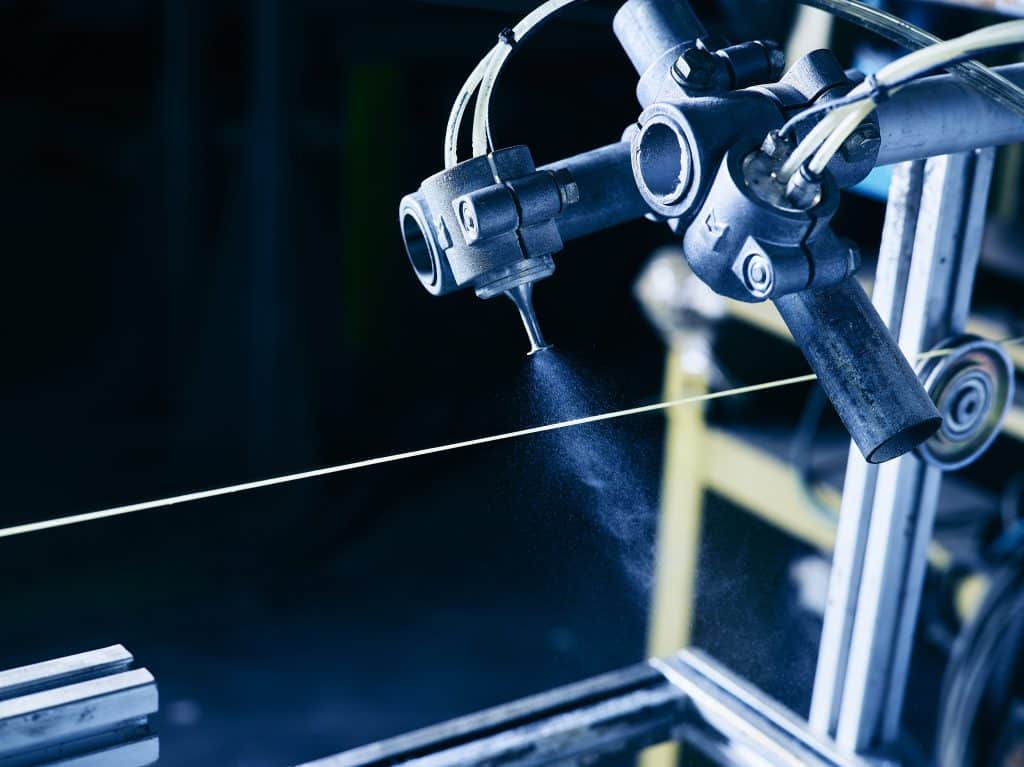

All technical and mechanical criteria are analyzed, including raw materials, assembly, construction, processing, finishing, and packaging.

If development is possible, the sales team will send you a quote and a delivery timeframe.

Once the quote and technical file have been approved, a prototype can be tested before being sent to you. We can have your product certified by the organization of your choice.

All our products undergo rigorous laboratory testing: breaking strength, impact strength, elongation, flexibility, knotability, sheath slippage, water shrinkage, etc.

All tests comply with the various ISO regulations and European standards in force.

Additional tests can be carried out on request.

Your request is ready for industrialization.

We are committed to meeting the deadline.

The group

COUSIN® french industry since 1848

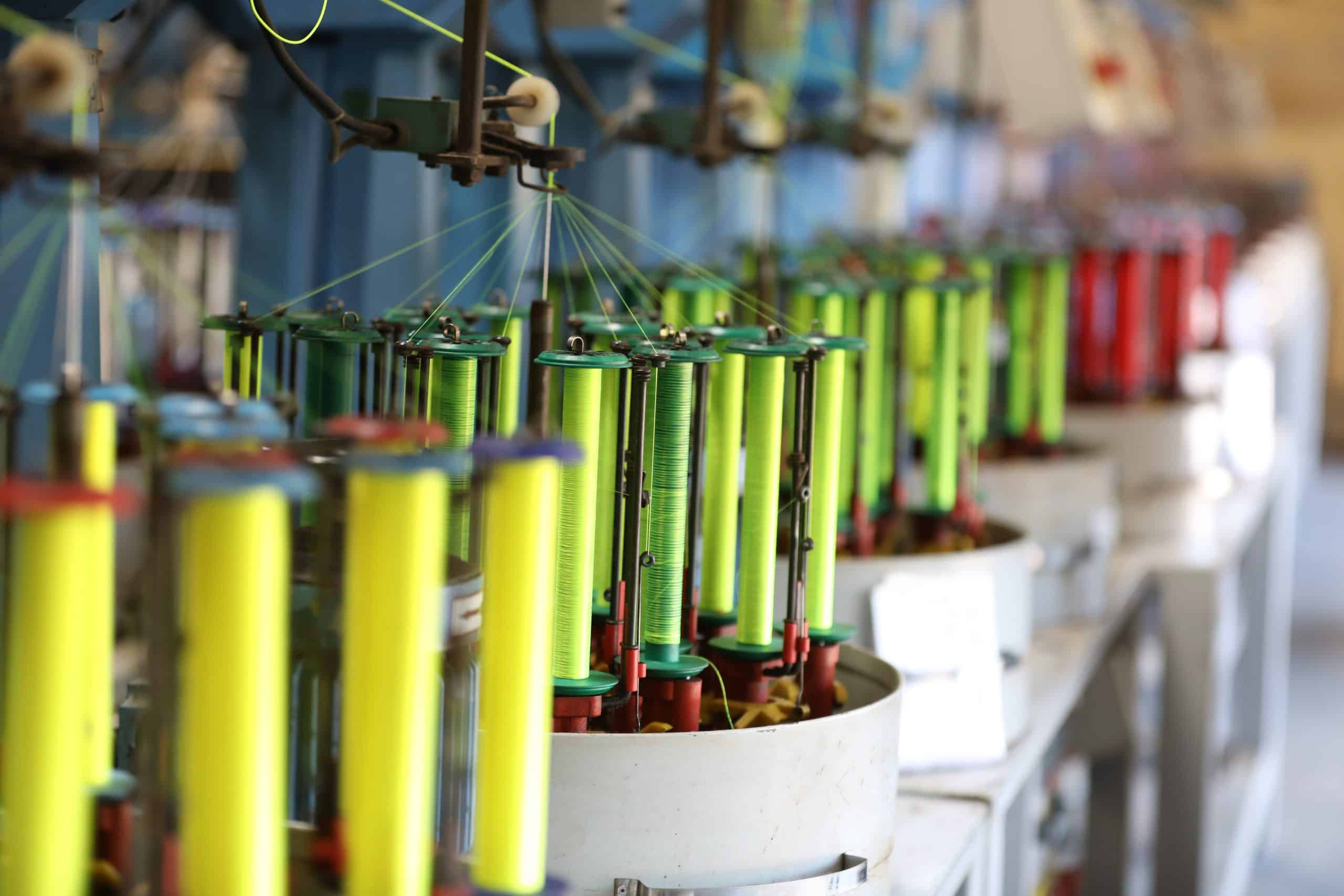

Since its creation in 1848, COUSIN® has positioned itself as an expert in fiber and technical rope designed for intensive use. In 1990, COUSIN spun off its activities into subsidiaries. The group has expertise as a manufacturer of ropes for sports and leisure activities (kitesurfing, water sports, climbing, etc.), for PPE for working at height, for industry, and for defense. The COUSIN® group has also become a major player in the manufacture of high-performance fibers and reinforced composites for all types of industries and dedicates part of its production to tennis and squash racket strings. Recent technological investments have positioned the group in the largest international markets.

In a few figures

- 177 years of experience

- 160 employees

- 60 countries all over the world

- 300 000 000 meters of finished products per year