Planet

The COUSIN® Group responds daily to social, economic, and environmental challenges.

After implementing initial visible actions and following the publication of its first carbon footprint assessment in 2024, an Impact Committee comprising nine employees with awareness of these issues was created to promote sustainable development topics and see them through to completion.

Our vision ? To align ourselves with the objectives set by the 2015 Paris Agreement, which aims to limit global warming to 2°C by 2050.

How does this relate to our industry ? Our goal is to reduce our carbon footprint by 24% by 2035 in order to stay on track.

To achieve this, actions are continuously being taken within our infrastructure, our teams, our business partners, and even our end customers. Here are a few examples:

BETTER SOURCED MATERIALS

We place quality and responsibility at the heart of our approach with our business partners. Our raw materials are rigorously selected from increasingly committed partners. We have made this a major selection criterion.

We are currently testing recycled fibers, such as polyester and polyamide, and natural fibers such as linen and pineapple skin fiber. Resins with a lower environmental impact are also being studied.

At the same time, we are developing a Rope2Rope project that aims to reintroduce fibers from used mountain ropes into our production chain.

By rethinking our supply chain, we are affirming our desire to combine industrial excellence with respect for the environment.

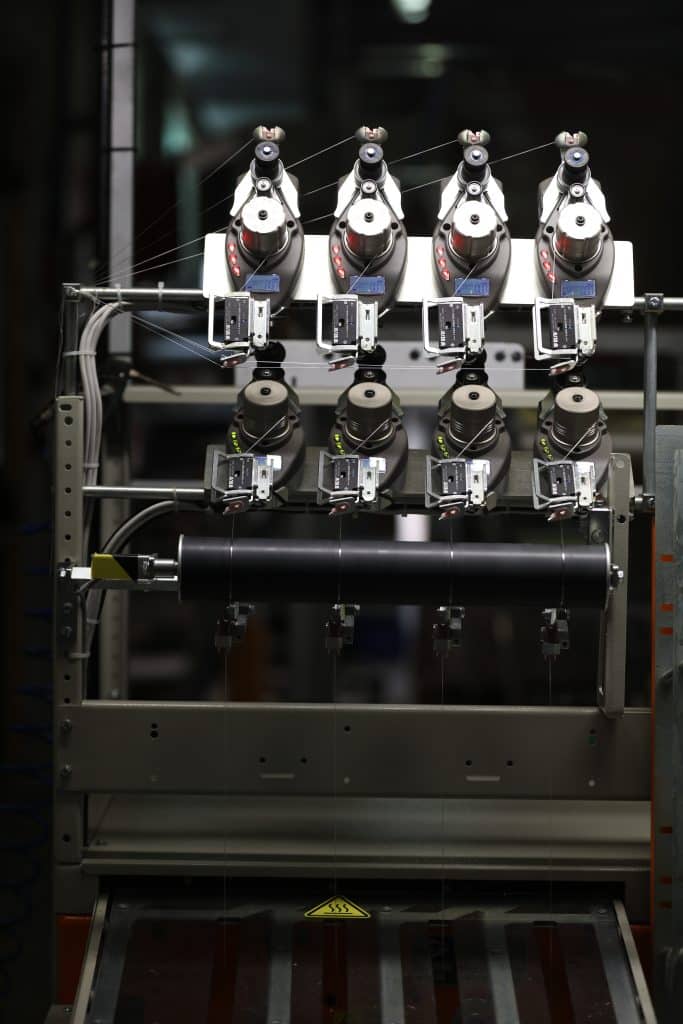

OPTIMIZED production tools

Our production and maintenance teams regularly work on optimizing our machines and industrial processes in order to limit the amount of scrap generated during production. Thanks to precise adjustments, the modernization of our equipment, and regular analysis of manufacturing flows, we reduce material losses at the source.

This approach not only conserves resources, but also improves our overall efficiency.

Less waste also means less waste to process and more added value at every stage. This commitment is fully in line with our responsible industrial strategy, which is geared towards sustainable performance..

PRODUCTION WASTE REINTRODUCED INTO OTHER CIRCUITS

Our production waste is systematically sorted by material type (polyamide, polyester, etc.). This sorting process ensures the purity of the waste for recycling purposes.

In terms of textile braids, during the twisting, assembly, and twisting stages, the yarn scraps generated in our workshops are taken back by partners in the automotive industry. Through a melt transformation process, they are reintegrated into the manufacture of technical parts, particularly dashboards.

Our production scraps from braiding are reintroduced into the manufacturing process for upcycled items (furniture, clothing, jewelry, accessories, etc.).

This approach is part of a controlled circular economy strategy: reducing the volume of non-recyclable waste, ensuring the traceability of secondary material flows, and creating industrial synergies.

PARTNERSHIPS THAT MAKE SENSE

We are committed to various economic and social causes.

For several years, we have been involved in the largest aeronautical projects of the decade, both industrial and academic, in partnership with Airbus, Arkema, and Stelia Aerospace, among others.

On a more social and economic level, we have been working with the Malecot group’s ESATs for over 10 years. Every day, 40 people with mental disabilities pack several hundred products. This is a professional reintegration program that can lead to on-site employment.

Finally, through technical partnerships, we are also involved in several meaningful projects. Through skipper Tanguy Le Turquais, we support the Lazare association, which creates supportive shared housing. Through skipper Laurent Bourgues, we support the Mon Bonnet Rose association, which raises awareness and helps people affected by breast cancer. Through TRR Racing, we support the Vulnérable movement.

These are all technical and social values that we share with our employees on a daily basis.

QUALITY OF LIFE AT WORK IS AT THE HEART OF OUR CONCERNS

Quality of life at work is a concrete priority. Our premises are historic, steeped in history, and have been modernized to offer modern, bright, and functional spaces. Relaxation rooms allow teams to recharge their batteries in a peaceful setting. The presence of sheep and beehives promotes biodiversity and creates a unique working environment in harmony with nature. Committed to an eco-responsible approach, we have implemented a structured waste sorting system and actions to raise employee awareness of sustainable practices. Each initiative aims to combine well-being, performance, and respect for the environment.