Technologies

Extrusion (monofilament, multifilament)

The company’s expertise in extrusion coating is a major strength. We now use this process to manufacture a wide range of monofilament and multifilament wires. This technology is applied across diverse sectors, from industry and sports to medical, construction, automotive, railway, and aerospace.

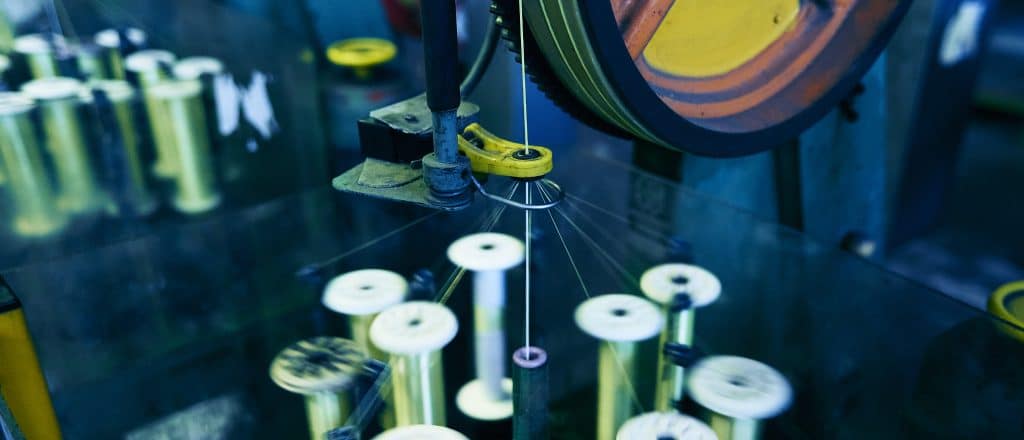

FIBER ASSEMBLY / COMMINGLING

Fiber assembly for thermoplastic composite applications. The introduction of blended or hybrid yarns represents a significant advancement in textile processing technology. This technology offers decisive advantages, particularly for thermoplastic applications. It enables the combination of carbon, glass, or natural fibers with various plastics such as polyamide 11 (PA11), polycarbonate (PC), polysulfone (PPS), polyetherimide (PEI), or polyether ether ketone (PEEK).

Integrating two different materials into a single yarn made from continuous filaments opens up new possibilities and applications – through knitting, braiding, weaving processes, or further developments.sur la technologie TFP.

Pultrusion

COUSIN® has developed a unique manufacturing process for FRP (Fibre Reinforced Products), primarily intended for reinforcing optical fiber cables.

These composite rods (reinforced with glass, aramid, or carbon) can also replace steel in many applications while being lighter, non-magnetic, and corrosion-resistant.

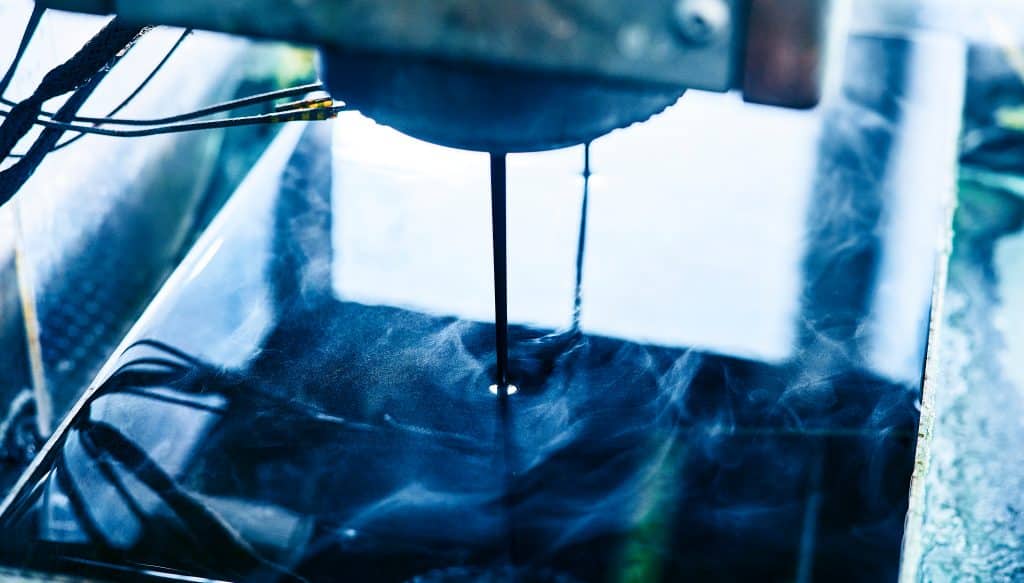

IMPREGNATION/COATING

The coating workshop is equipped with numerous impregnation lines for processing textile strands individually or in bundles.

Regardless of the type of yarn being treated glass, carbon, aramid, polyester, or high molecular weight polyethylene a wide range of resins can be used for impregnation: polyurethane, acrylic, silicone, PVC, and more.

The desired properties may include : abrasion resistance, improved UV resistance, fire-retardant properties, etc.

BRAIDING

We also specialize in braiding technologies, with the possibility of resin impregnation.